In 2017 and 2018, Precision Optical successfully manufactured multiple large optical flats. These reference optics had apertures > 600mm, and some weighed nearly 200 lbs.! With months of engineering, design reviews, and tooling and equipment development, Precision Optical was able to repeat the necessary optical performance to prove that we could deterministically achieve success.

Key to this success was properly facilitating the physical moving of the substrate material from department-to-department, the loading of the substrates into the necessary staged equipment, the hoisting and flipping of the substrates, the proper mounting of the optical flats for interferometric testing, and of course the proper packaging for transit.

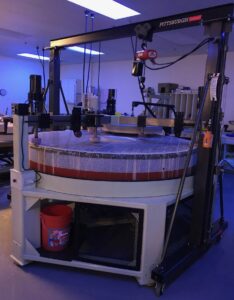

On top of the challenges with general workmanship and handling, Precision Optical was tasked with achieving extremely accurate surface form across the entire aperture of each optical flat and applying the necessary thin film coatings. With regard to measuring surface form, we did so without having a 24” aperture interferometer. Rather, we combined custom-built tooling and support fixturing to stitch sub-apertures inspected over 18”.